July 28, 2016

As a communications subsystem, a fiber optic data link connects inputs and outputs (I/O) from electronic subsystems and transmits these signals over fiber optic cables. More specifically, this data link converts an electrical input signal into an optical signal, then sends the optical signal over an optical fiber, and finally converts the optical signal back to an electrical signal, actually operating an alternative to copper cabling or a wireless subsystem. There are three parts included in a fiber optic data link: transmitter, optical fiber, and receiver. And most systems use a transceiver which includes both transmitter and receiver in a single module. This article is intended to introduce some basic information about fiber optic data link, such as its parts, signals and protocols, as well as performance.

A fiber optic transceiver used on each end of a link includes a transmitter and receiver that convert electrical signals to optical signals and vice versa for transmission over optical fiber. The typical data link transmits over two fibers for full duplex links, one fiber in each direction. Some links may allow transmission at several wavelengths of light simultaneously over a single fiber in each direction, called wavelength-division multiplexing (WDM).

The transmitter consists of an interface circuit and a source drive circuit. The transmitter's drive circuit converts the electrical signals to an optical signal by varying the current flow through the light source. The two types of optical sources are light-emitting diodes (LEDs) and laser diodes.

The receiver converts the optical signal exiting the fiber back into an electrical signal. It consists of two parts: the optical detector and the signal-conditioning circuits. An optical detector detects the optical signal. The signal-conditioning circuit conditions the detector output so that the receiver output matches the original input to the transmitter. The receiver should amplify and process the optical signal without introducing noise or signal distortion. Noise is any disturbance that obscures or reduces the quality of the signal. Noise effects and limitations of the signal-conditioning circuits cause the distortion of the receiver's electrical output signal.

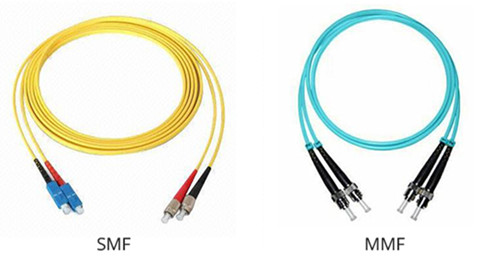

Transceivers are designed to work over one specific type of fiber decided by the distance and bandwidth of the communications. For instance, Cisco MGBLX1, a 1000BASE-LX SFP, is dedicated to work over single-mode fiber (SMF) for maximum 10km link length at 1310nm wavelength. HP J4858C, a 1000BASE-SX SFP is designed to operate through multi-mode fiber (MMF) for maximum 550m link length at 850nm wavelength. SMF is used for significantly longer links while MMF for shorter links.

Fiber optic data links may transmit signals that are either analog or digital and of many different, usually standardized, protocols, depending on the communications system(s) it supports. Data links may be protocol transparent, but may also include data encoding to provide more robust data communications. They may be specified by the application or standardized network which they are intended to support, or by the types and bandwidth of signals that they are designed to transmit.

Analog signals are continuously variable signals where the information in the signal is contained in the amplitude of the signal over time. They are the natural form of most data, but are subject to degradation by noise in the transmission system. As an analog signal is attenuated in a cable, the signal to noise ratio becomes worse so the quality of the signal degrades. In contrast, digital signals are sampled at regular time intervals and information is a digital number. They can be transmitted long distances without degradation as the signal is less sensitive to noise.

The power budget is the difference between the output power of the transmitter and the input power requirements of the receiver. The receiver has an operating range determined by the signal-to-noise ratio (S/N) in the receiver. The S/N ratio is generally quoted for analog links while the bit-error-rate (BER) is used for digital links. BER is practically an inverse function of S/N.

The power of the receiver is determined by the output power of the transmitter, and diminished by the loss in the cable plant primarily, but other factors may also affect power budget performance. When the power budget is inadequate for the loss in the cable plant, higher power transmitters or more sensitive receivers or higher bandwidth cable plant are required.

In typical applications, a fiber optic data link serves as a communications medium attached to electronics on either end that provide the other services necessary for communications over the link. Its each part is responsible for the successful transfer of the data signal. As a professional fiber optic product supplier, Fiberstore offers various kinds of fiber optic transceivers e.g. MGBLX1), and optical fibers (e.g. LC fiber cable). You can visit Fiberstore for more information about fiber optic data link products.

Posted by: fernxu123 at

02:32 AM

| Comments (2)

| Add Comment

Post contains 806 words, total size 6 kb.

July 21, 2016

To accommodate the increasing demands for high-speed data transmission and great data capacity, data centers are moving to 40G and 100G transmission networks now. It’s known that 40/100G Ethernet implementations over multi-mode fibers (MMFs) use multiple parallel 10G connections that are aggregated. 40G uses four 10G fibers to send and four 10G fibers to receive, while 100G uses ten 10G fibers in each direction. To ensure that fiber systems work smoothly, each fiber must have a transmitter at one end, and a receiver at the other.

For multi-fiber arrays using MPO/MTP connectors, the TIA 568 standard provides three methods for configuring systems to ensure that proper connections are made, Methods A, B & C. Each of these methods handle the transition from a transmit position to a receive position in a slightly different manner. This article mainly discusses MPO/MTP polarity and its components in 40/100GbE transmission, and the rest passages will only mention MTP instead of MPO/MTP for simpleness.

MTP connector: Each MTP connector has a key on one side of the connector body. When the key sits on the bottom, this is called key down. And when the key sits on top, this is referred to as the key up position. In this orientation, each of the fiber holes in the connector is numbered in sequence from left to right. Here refers to these connector holes as positions, or P1, P2, etc.. Each connector is additionally marked with a white dot on the connector body to designate the position 1 side of the connector when it is plugged in.

MTP Adapter: MTP adapter is used to connect two MTP connectors. This adapter on a cassette is simply a holder with keying designed to hold the two facing ends of the MTPs in correct alignment. The following image shows how the two MTPs are held with the adapter.

MTP Cable: MTP trunk cables serve as a permanent link that connects MTP modules to each other. Available with 12, 24, 48 and 72 fibers, these cables are used to facilitate rapid deployment of high density backbone cabling in data centers and other high fiber environments reducing network installation or reconfiguration. A 72-fiber MTP trunk cable can be terminated with 6 MTP connectors which are manufactured specifically for multi-fiber loose tube or ribbon cable.

MTP harness cables are often terminated with a male/female connector on the MTP side and several duplex LC/SC connectors on the other side, providing a transition from MMFs to individual fibers or duplex connectors. This kind of cable assembly provides a reliable, cost-effective cabling system for migrating from legacy 10G to higher speed 40G/100GbE. For instance, 12-fiber MTP to 4 duplex LC can be used to connect four 10 gig SFP (SFP-10G-SR) with one 40G QSFP+ module (40G-QSFP-SR4).

MTP Cassette Modules: These modules permit rapid deployment of high density data center infrastructure as well as improved troubleshooting and reconfiguration during moves, adds and changes. They enable users to take the fibers brought by a trunk cable and distribute them to a duplex cable. As already assembled units, the MTP cassette modules are fitted with 12 or 24 fibers and have LC, or SC adapters on the front side and MTP at the rear, this is to say, inside a standard LGX cassette module, there is a hydra cable.

Method A, Method B and Method C are the defined methods by TIA 568 standard for proper polarity. To understand these methods, MTP truck cables are used as the object.

Method A: For this method, the transmitâ€receive flip must happen in the patch cords, and the trunk cable is a straight through transmission, with the key up on one end, and the key down on the opposite end(image below).

Method B: This method uses key up connector on both ends of the cable. This type of array mating results in an inversion, which means the fiber positions are reversed at each end. The fiber at P1 at one end is mated with fiber at P12 at the opposing end.

Method C: This method one key up connector and one key down connector. Each adjacent pair of fibers at one end are flipped at the other end. For example, the fiber at position 1 on one end is shifted to position 2 at the other end of the cable. The fiber at position 2 at one end is shifted to position 1 at the opposite end etc.

For 40G transmission using 12-fiber MTP connectors, it transmits 40G using four parallel 10G lanes in each direction. More specifically, there are eight lanes within twelve total positions being employed for transmitting and receiving signals. The four leftmost positions are used to transmit, and the four rightmost positions are used to receive, leaving the four in the center are unused.

For 100G transmission, there are multiple configurations (shown above). However, increasingly it appears that the single port 24-fiber connector is the preferred approach once connector loss is improved.

When it comes to the high networking capacity, it’s no doubt that MTP cable comes as the suitable solution. Select the right polarity method, and then high density and reliability can be achieved. As a professional fiber patch cord manufacturer, Fiberstore supplies various MTP components, including MTP cables, adpaters, connectors, cassettes. You can try here.

Posted by: fernxu123 at

03:08 AM

| No Comments

| Add Comment

Post contains 897 words, total size 8 kb.

July 19, 2016

Copper wires were one the great inventions that let people to power the first telegraphs and telephones, allowing communication over long distances and bringing benefits to people’s daily life. Owing to the advances made in fiber optic technology, coppers are giving way to fiber optics, namely, fiber optic cables, which are used in many applications, from delivering television signals to homes to transferring data between computers that are thousands of miles apart. And when it comes to computer networks, fiber optic cables’ usage is even more obvious.

Installing and maintaining computer networks isn’t tricky, if you follow the step-by-step instructions which will be discussed in details later. Before delving into this topic, let’s first explain some basic information about fiber optic cables.

A fiber optic cable is a cable containing incredibly thin strands of glass or plastic, that can have as few as two strands or as many as several hundred. Its ends are capped with the same or different connectors. Take LC SC cable for example, one side is terminated with LC, and the other side is SC.

Fiber optic cables carry information between two places in the form of light pluses. Light travels down a fiber-optic cable by bouncing repeatedly off the walls. Each tiny photon (particle of light) bounces down the pipe like a bobsleigh going down an ice run. Now you might expect a beam of light, traveling in a clear glass pipe, simply to leak out of the edges. But if light hits glass at a really shallow angle (less than 42 degrees), it reflects back in again—as though the glass were really a mirror. This phenomenon is called total internal reflection. It's one of the things that keeps light inside the pipe.

Although copper has been used in a variety of applications since the 1920s, as it’s inexpensive, easy to use, and a great conductor for electricity. But when compared with fiber optic cable, it’s impossible to deny the great bandwidth capacity even at long distances provided by fiber optic cables. Light has a very high frequency that enables fiber optic cable to carry much more information at any given time. This makes it ideal for applications that use up a lot of bandwidth, like streaming music or video conferencing. Perhaps more importantly, fiber optic cable can carry data much farther than regular copper cables. Besides, fiber optics are also resistant to corrosion, making them a good option for beachfront properties where copper cabling would otherwise be susceptible to degradation by salt and seawater.

To install fiber optic cables on computer networks is not as simple as plugging everything in, but its manageable within people’s abilities.

Firstly, it’s important to choose the right cable type for the computers. There are two main types of fiber optic cables: single-mode fiber (SMF) and multi-mode fiber (MMF). The former is more expensive, but able to transmit 10 gigabits per second up to 37 miles. The latter is used for short distances, up to 1800 feet, able to transfer up to 10 gigabits of data per second. For most office or home networks, the latter is preferable, since there's really no need to cover very long distances.

After selecting the right cable type, here goes the detailed installation guide.

Installation Process- Place all the devices in the right position that will be included in the network. The hubs and switches should be placed near the main computer and the wall outlet (for integrated fiber in the loop, IFITL connections). Connect the computer to the wall outlet using the cable and connect the hubs and routers to the computer.

- Add a fiber optic cable to the hub or router and connect it to a second computer to be added to the network. Ensure that there's enough slack in the cable so it's not too tight and easily unplugged. Secure the cables with ties.

- A media converter is necessary for devices that have no fiber optic outlet. This converter changes the light pulses into electricity. Plug this into the computer with a USB or Ethernet cable. Plug in any workstation without a fiber optic outlet into the converter.

- Turn on all the devices and computers on the network.

- Install additional software and drivers on devices if needed.

As for indoor computer networks, most importantly, it’s imperative to make sure that none of the installed fiber optic cables are disconnected or damaged. Cables should be neat and tied together to prevent accidents, and of course, should be kept away from young kids and pets. Fiber optic cables can experience slow or unreliable connections due to excess dust, scratches, or even humidity. An inexpensive laser pointer can help check if the cable is working. Point the laser into one end of the cable and see if the other end lights up. If it does, this means the cable is conducting light properly. If not, the cable will have to be cleaned or replaced.

Fiber optic cables make it possible to send and receive light signals at large amount over long distances. Many applications have replaced copper wires with fiber optic cable, since they allow higher bandwidth and faster speed, resistant to EMI and insensitive to extreme weather conditions. For those who want to buy fiber optic cables, Fiberstore is a good place, available with numerous choices of different types, single-mode (fiber optic patch cables single mode) and multi-mode (LC-SC multimode fiber patch cord). A good site for your cable choice.

Posted by: fernxu123 at

03:06 AM

| No Comments

| Add Comment

Post contains 947 words, total size 7 kb.

July 17, 2016

It’s known that multi-mode (MMF) fiber is available in OM1, OM2, OM3 (e.g. OM3 patch cable) and OM4 versions. How about single-mode fiber (SMF)? There are a variety of SMFs with carefully optimized characteristics available commercially: ITU-T G.652, 653, 654, 655, 656 or 657 compliant. Since several types exist, do you know how to choose a right SMF type to light-up your multi-terabit per second system? The past decades has witnessed the evolution of SMF designs, and most deployed SMFs nowadays are G.652D, G.655 or G.656 compliant fibers. (G.657A is essentially a more expressive version of G.652D, with a superior bending loss performance.) So, in this text, discussion is made on choosing G.652D, G.655 and G.656 compliant fibers against three parameters: attenuation, PMD and CD.

Attenuation is the reduction or loss of optical power as light travels through an optical fiber and is measured in decibels per kilometer (dB/km). G.652D offers respectable attenuation coefficients, when compared with G.655 and G.656. However, It should be remembered that even a meager 0.01dB/km attenuation improvement would reduce a 100km loss budget by a full dB - but let's not quibble. No attenuation coefficients for G.655 and G.656 at 1310? It was not, as you may immediately assume, an oversight. Both G.655 and G.656 are optimized to support long-haul systems and therefore could not care less about running at 1310nm. A cut-off wavelength is the minimum wavelength at which a particular fiber will support SM transmission. At ≤1260nm, G.652D has the lowest cut-off wavelength - with the cut-off wavelengths for G.655 and G.656 sitting at ≤1480nm and≤1450 respectively - which explains why we have no attenuation coefficient for them at 1310nm.

PMD, polarization-mode dispersion, is an unwanted effect caused by asymmetrical properties in an optical fiber that spreads the optical pulse of a signal. Slight asymmetry in an optical fiber causes the polarized modes of the light pulse to travel at marginally different speeds, distorting the signal and is reported in ps / √km, or "ps per root km". Oddly enough, G.652 and co all possess decent-looking PMD coefficients. Now then, popping a 40-Gbps laser onto fiber up against an ultra-low 0.04 ps / √km, the calculator reveals that the PMD coefficient admissible fiber length is 3,900 km and even at 0.1 ps / √km, a distance of 625km is achievable.

PMD is particularly troublesome for both high data-rate-per-channel and high wavelength channel count systems, largely because of its random nature. Fiber manufacturer’s PMD specifications are accurate for the fiber itself, but don’t incorporate PMD incurred as a result of installation, which in many cases can be many orders of magnitude larger. It is hardly surprising that questionable installation practices are likely to cause imperfect fiber symmetry - the obvious implications are incomprehensible data streams and mental anguish. Moreover, PMD unlike chromatic dispersion is also affected by environmental conditions, making it unpredictable and extremely difficult to find ways to undo or offset its effect.

CD is called chromatic dispersion to emphasize its wavelength-dependent nature, and it has nothing to do with the loss of light. This phenomenon occurs because different wavelengths of light travel at different speeds. Thus, when the allowable CD is exceeded - light pulses representing a bit-stream will be rendered illegible. It is expressed in ps/ (nm·km). At 2.5-Gbps CD is not an issue - however, lower data rates are seldom desirable. But at 10-Gbps, it is a big issue and the issue gets even bigger at 40-Gbps.

G.652D’s high CD coefficient is very poor next to the competition. G.655 and G.656, variants of non-zero dispersion-shifted fiber (NZ-DSF), comprehensively address G.652D’s shortcomings. It should be noted that nowadays some optical fiber manufacturers don’t bother with distinguishing between G.655 and G.656 - referring to their offerings as G.655/6 compliant.

It seems that this approach creates more problems than it is likely to solve - by unacceptably amplifying non-linear four-wave mixing and limiting the fiber to single-wavelength operation - in other words, no DWDM. That, in fact, is why CD should not be completely lampooned. Research revealed that the fiber-friendly CD value lies in the range of 6-11 ps/nm·km. Therefore, and particularly for high-capacity transport, the best-suited fiber is one in which dispersion is kept within a tight range, being neither too high nor too low.

After discussion, it’s clear to make the conclusion that only thing that genuinely separates fiber types for high-bit-rate systems is the third parameter: CD. Actually, one of the most important considerations in the fiber selection process is the fact that optical signals may need to be amplified along a route, which will be discussed in other articles.

Different kinds of SMFs have different characteristics. Hope this passage help you obtain a clear understanding of three parameters considered in single-mode fiber selection. As a professional fiber patch cord manufacturer, Fiberstore supplies various kinds of SMFs for long-haul applications, like LC to LC fiber patch cable single mode. Certainly, MMFs can also be found here. You can visit Fiberstore for more information about fiber optic cables.

Posted by: fernxu123 at

02:46 AM

| No Comments

| Add Comment

Post contains 852 words, total size 7 kb.

July 14, 2016

Over the years, data center bandwidth requirements are expanding at double-digit rates, along with the equally urgent push not to compromise the cost-to-performance ratio. To accommodate the needs of web-scale data centers and cloud-based services, efforts have been made by leading cloud and telco providers to define and drive 25Gigabit Ethernet (GbE) technology. As such, the latest Ethernet speed upgrade path would be 10G-25G-100G, or the possible 10G-25G-50G-100G, instead of 10G-40G-100G. The occurrence of 25GbE changes the data center Ethernet landscape of some enterprises and organizations, creating a viable market for high-speed, reasonably-priced connectivity. How much do you know about this 25GbE network? You may have few insights on it. Don’t worry, this article gives an detailed description about it.

25GbE is defined for 100GbE which is implemented as four 25Gbps lanes running on four fiber or copper pairs. 100G optics (e.g. QSFP28 transceivers) have four lasers, each transmitting at 25Gbps. The twisted pair standard was derived from 40GbE standards development. Using 25GbE with QSFP28 transceivers results in a single-lane connection similar to existing 10GbE technology—but it delivers 2.5 times faster performance. It’s a proposed standard for Ethernet connectivity that will benefit cloud and enterprise data center environments, enabling the transmission of Ethernet frames at 25Gbps, and promoting the standardization and improvement of the interfaces for applicable products. The following table provides a summary of key 25GbE interfaces.

One of the main challenges in data centers is the insatiable hunger for more bandwidth. In 2010, the IEEE ratified a 40GbE and 100GbE standard, and launched a new study group to work on a 400GbE standard to keep up with bandwidth demand.

However, for some cloud providers and other large-scale data center operators, the requests are not more than the simple raw capacity. 10GbE is no longer fast enough. For server to top-of-rack network connections to keep up, you would need to double the number of switches in each rack and use 10GbE NICs. This would lead to impractical budget. The 40GbE isn't cost-effective or power-efficient in top-of-rack (ToR) switching for cloud providers and others that operate at a similar scale.

In such a condition, 25GbE was proposed as a standard for Ethernet connectivity, using a single-lane 25Gbps Ethernet link protocol to deliver the best price per performance ratio. In June 2014, the 25GbE Consortium was formed to promote the technology, and subsequently an IEEE 802 workgroup was formed to develop the standard.

Compared with 40GbE solutions, 25GbE technology provides superior switch port density by requiring just one lane (vs. four with 40GbE), along with lower costs and power requirements. Since 40G short-reach QSFP+ interface is constructed from four parallel links. Extending QSFP+ onto fiber requires four parallel 10Gb streams to transport this to the receiving QSFP+ parallel optics. And long-reach QSFP+ interfaces utilize Wave Division Multiplexing (WDM) to transport the four 10Gb streams over a single pair of fiber (image below). The requirement of four lanes significantly reduces switch port density per switching chip and increases the cost of cabling and optics. While the 25GbE standard requires only a single lane, while delivering 2.5 times more throughput compared to current 10GbE solutions, saving the cost compared to 40GbE solutions.

Besides, deploying 25GbE networks enables organizations to significantly reduce the required number of switches and cables, along with the considerations for the reduction of facility costs related to space, power, and cooling compared to 10GbE and 40GbE technology. Fewer physical network components reduce ongoing management and maintenance costs.

Additionally, the 25GbE physical interface specifications support the form factors, including QSFP28 and SFP28. QSFP28 has four lanes and each lanes supports 25Gbps speed. Each lane requires a serializer/deserializer (SerDes) chipset. The proposed 25GbE standard uses the same physical silicon from a single 25Gbit/s lane, which simplifies the process with just minor changes for forward error correction and lane alignment.

25GbE standard helps reduce capital expenditures (CAPEX) and operational expenditures (OPEX) compared to 40GbE, while meeting the necessary I/O bandwidth requirements in data centers. In addition, some blade server chassis solutions today are limited to only two SerDes lanes for their LAN on Motherboard (LOM) networking ports and therefore cannot implement a four-lane 40Gbps interface.

25GbE specification enables network bandwidth to be cost-effectively scaled in support of next-generation server and storage solutions residing in cloud and web-scale data center environments. At present, Fiberstore supplies many 25G solution products, including QSFP28 to 4xSFP28 DAC cables which serve as the alternative solutions to QSFP28 to QSFP28 DAC (QSFP28 cable). With the technology being much maturer, more and more 25G products will be made available to users.

Posted by: fernxu123 at

02:44 AM

| No Comments

| Add Comment

Post contains 780 words, total size 7 kb.

July 12, 2016

When it comes to the information transmission, three ways are usually discussed. For landline telephone, a wire cable is used to carry the sounds from voice into a socket in the wall, where another cable takes it to the local telephone exchange. As to cellphones, information is traveled through invisible radio waves, a technology called wireless. The third way utilizes the fiber optics, which sends information coded in a beam of light down a glass or plastic pipe. Fiber optic cable is made up of incredibly thin strands of glass or plastic known as optical fibers, whose ends are often capped with the same (SC SC) or different connectors (LC SC) to form fiber optic patch cable , or called fiber optic jumper.

Nowadays, fiber optic cable has been praised for their high-performance capacities. But in practical use, it also troubles installers and users. Not only does the fiber installation process need great care and attention, but also the troubleshooting process is a little tricky. Today, this text will discuss some common problems with fiber optic cables and how to troubleshoot these faults.

To diagnose and repair faults quickly and efficiently, it’s necessary to know some common fiber optic cable problems with the possible causes:

- Broken fibers owing to physical stress or excessive bending;

- Signal signal loss because of a contaminated connector or a cable span that’s too long (faulty splices or connectors also lead to excessive signal loss);

- Faulty connection of fiber to the patch panel or in the splice tray;

- Insufficient transmitting power;

It’s known that the fiber break causes a dead connection. But if there occurs intermittent connection, then what causes it? Here are some possible causes. The cable’s attenuation may be too high because of poor quality splices or too many splices. Or connectors are contaminated by such things as dust, fingerprints, scratches, and humidity. Besides, low transmitter strength and bad connections in the wiring closet all bring about intermittent connection.

While working on fixing this fault problem, the first thing to do is to gather information as much as possible, about the problem’s symptoms and possible causes. Then you can start from the following points.

- Information Collection

It’s imperative to know if the PC has been disconnected or has moved recently. If the fiber optic cable has been disconnected from the PC, it could be that the cable was never reconnected, was reconnected incorrectly, or was contaminated during the time that it was disconnected.

Any changes to the PC’s hardware also cause problems, so it’s important to find out whether the PC’s hardware has been upgraded or not. It’s possible that the cable was never disconnected during the hardware upgrade. If so, there’s a chance that the cable could have been overextended when the PC was moved, or the PC could have been accidentally smashed against the back of the desk or the wall, damaging the connector.

In addition, there is a chance that the cable was never damaged or hooked up incorrectly, but rather that the new hardware is preventing the NIC from working correctly. The exact method by which you’d determine whether or not the NIC is having problems varies with your operating system.

Before repairing fiber optic cable problems, it’s also of great importance to keep in mind that fiber cable can be destroyed if stepped on or bent too sharply, or if a chair is rolled over it.

- Fault Testing

After gathering enough information, now goes to problem diagnosis process.

One way is to disconnect both ends of the fiber cable and hold a laser pointer (image left) up to the cable to see if the light comes out the other end. Or if a laser pointer is unavailable, a bright flashlight (image right) works just as well.

- Testing Results

If no light comes through the cable, then the cable is broken and needs to be replaced. If light does come through the cable, it doesn’t necessarily mean that the cable is good; it just means that the fiber inside the cable hasn’t been completely destroyed. However, if the light comes through the cable and the cable run is shorter than a hundred meters, then the cable will often be good enough to use.

Certainly, there exist other diagnostic techniques, like to disconnect the troubled computer from the fiber optic cable and connecting a PC or laptop to the cable. If the good PC is able to function, then the cable is free from the problem. And the problem could lie in the damaged NIC, or a configuration that could be preventing the computer from recognizing the NIC properly.

If you’re familiar with copper wires, then you may discover that fiber optic cable is totally different, and it’s very fragile. When running fiber optic cable for different applications, there is high chance that problems will occur. In this case, understanding what are possible causes and how to deal with them is helpful in solving problems easily. Of course, although problems exist, the fiber optic cables themselves chosen for project should be of high quality. As a professional fiber patch cord manufacturer, Fiberstore supplies many fiber cable types for various applications, test-assured and cost-effective, like SC SC fiber cable. A good place for your cable choice.

Posted by: fernxu123 at

02:50 AM

| No Comments

| Add Comment

Post contains 891 words, total size 7 kb.

July 05, 2016

Data center, which is full of fiber optic cables (such as fiber cable LC to LC), optical modules, and many other optic products, is the brain of a company and the place where the most critical processes are run. Today we are gonna talk about what they contain, and how they are operated.

Although we have mentioned it above that data center is made up of many optics, there is another important point - large-scale computer systems that have been around it for a while. Computers, certainly, require electricity, as well as protection from theft and the accidental or intentional manipulation of hardware. Put simply, one has to safeguard data centers against external influences and provide them with sufficient cooling. After all, there is a lot of powerful hardware sitting in one place.

In addition to these "hard†factors, one must also take into consideration organizational measures, such as periodic backups that ensure operability. As a rule, the more extensive and critical the hardware and software become, the more time and effort are required to provide optimal protection.

For that reason, a data center preferably consists of a well-constructed, sturdy building that houses servers, storage devices, cables (say OM3 patch cable), and a connection to the Internet. In addition, the center also has a large amount of equipment associated with supplying power and cooling, and often automatic fire extinguishing systems. So next, let’s figure out how a data center works according to power supply and cooling these two aspects.

The data center is connected to two separate grid sectors operated by the local utility company. If one sector were to fail, then the second one will ensure that power is still supplied.

In addition, the data center has 13 diesel generators, which are housed in a separate building. Together, they can produce a total of 29 megawatts, an output that is sufficient to cover the data center’s electricity demand in an emergency. The diesel motors are configured for continuous operations and are always in a preheated state so that they can be started up quickly in the event of an incident. It only takes an outage in just one of the external grid sectors to automatically actuate the generators.

Both the local utility company and the diesel generators deliver electricity with a voltage of 20 kilovolts (kV), which is then transformed in the data center to 220 or 380 volts.

Within the data center, block batteries ensure that all operating applications can run for 15 minutes. This backup system makes it possible to provide power from the time a utility company experiences a total blackout to the time that the diesel generators start up.

The uninterruptible power supply (UPS) also ensures that the quality remains constant. It compensates for voltage and frequency fluctuations and thereby effectively protects sensitive computer electronic components and systems.

A redundantly designed power supply system is another feature of the data center. This enables one to perform repairs on one network, for example, without having to turn off servers, databases, or electrical equipment.

Several servers or storage units have multiple, redundant power supply units, which transform the supply voltage from the two grid sectors to the operating voltage. This ensures that a failure of one or two power supply units does not cause any problems.

As we know, the electronic components will generate heat when in operation. In order to keep data center operate smoothly, cooling a data center is essential, and because of the concentrated computing power, the costs to do so are considerable.

As a result, servers are installed in racks, which basically resemble specially standardized shelves. They are laid out so that two rows of racks face each other, thereby creating an aisle from which the front side of the server is accessible. The aisles are covered above and closed off at the ends by doors. Cool air set to a temperature of 24 to 26°C is blown in through holes in the floor, flows through the racks, and dissipates the heat emitted by the servers.

At higher outside temperatures, the air-conditioning systems are cooled with water, made possible by six turbo-cooling units. They are not all used to cool the data center, given that some are used as reserve units. Should a cooling system fail, the time until the backup unit is operational must be covered. To that end, 300,000 liters of ice-cold water (4°C) are available to absorb the heat from the air-conditioning systems during this period.

To top it off, the turbo-cooling units also have to dissipate heat. There are 18 heat exchangers on the data center’s roof for this purpose, which release hot air into the environment.

If outside temperatures is above 26°C, the heat exchangers are sprinkled with water in order to make heat dissipation more effective through evaporative cooling. The large amounts of water consumed in the summer are covered by waterworks allocated to the data center. The municipal water supply system provides a reserve supply in this case and acts as a failsafe.

After reading this article, hope you have an overview of data center. Anyway, data center is so important for an enterprise that it can help us in how we can provide the strongest offering to our customers. In some day, data center may be synonymous with network operations center (NOC), a restricted access area containing automated systems that constantly monitor server activity, Web traffic, and network performance. And we are really looking forward to it!

Posted by: fernxu123 at

03:00 AM

| No Comments

| Add Comment

Post contains 923 words, total size 7 kb.

34 queries taking 0.1065 seconds, 91 records returned.

Powered by Minx 1.1.6c-pink.