August 08, 2016

Almost every user encounters the similar problem: the Internet is not fast enough. The slow response to net surfing isn’t just browser latency, but also about the network interconnections themselves. To put it simply, increased viewing of TV and downloading of videos further burdens the Internet. Despite some bandwidth-hunger applications are faster than ever, the carrier backhaul networks slow everything down. On top of that, the cloud computing applications require considerably faster networks. Coming to this solution are fiber optic networks.

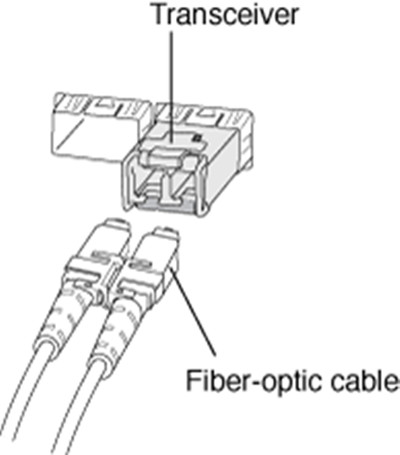

In each fiber optic network, a fiber optic transceiver and an optical fiber constitute the fiber optic data link. The transceiver is designed to operate over specific fiber cable type. For instance, SFP-10G-SR, a Cisco compatible 10GBASE-SR SFP+, is manufactured to work on multi-mode fiber (MMF). Optical fiber has been adopted in many high-performance optical networks. In a word, fiber optics offers other benefits besides simple speed. These benefits do, however, require expertise in the design of fiber optic cable in order to prevent difficult-to-diagnose failures.

Just mentioned above, fiber optics boasts of many advantages, some of which pack a significant punch in aerospace and defense applications. Actually, airborne applications were among the first to adopt fiber-optic-based design. In such an environment, weight, reliability, and immunity from electromagnetic interference (EMI) are critical concerns. And given the use of airborne platforms in graphics- and processing-intensive Command, Control, Communications, Intelligence, Surveillance, and Reconnaissance (C3ISR) functions, an enclosure must be designed to support extremely high-performance computing.

- Fiber vs. Copper: Cost & Weight

To compare the overall costs of the configuration in the boxes shown above through fiber and Quadrax, a few basic assumptions must first be made. First, for shorter cables, little cost difference exists between optical fiber and Quadrax; however, fiber becomes more expensive for longer runs. Regarding the connectors, while fiber connectors are more expensive than Quadrax, they also support a higher density.

When it comes to the weight savings in the same configuration, though, the reasons to opt for this increased cost become obvious, particularly in airborne and other weight-sensitive applications. While connector weights are roughly the same, the optical cable itself is significantly lighter than Quadrax. Such weight economy also has the added benefit of making optical fiber much less prone to the chafing that arises due to vibration, which can significantly impact Quadrax.

All those explain why fiber-based designs have been so widely adopted in airborne applications ahead of others.

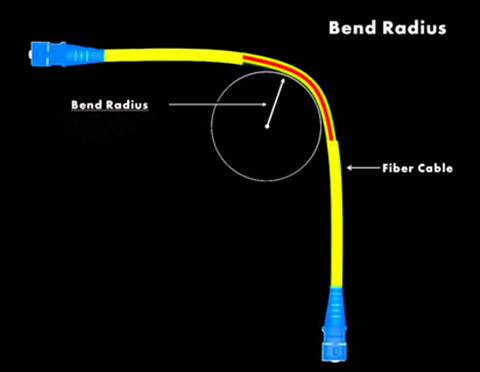

Once it’s decided that fiber optic cable benefits make is applicable for the environment, fiber-specific routing and handling expertise is required to ensure that the resulting system provides the performance, serviceability, and long-term reliability required by applications. Providing strain relief, and minimizing bend radius for optical fiber, are of paramount concern. To understand some basics of handling fiber optic cable, it’s necessary to know about the use of pull-proof connectors with loose-structure cable and non-pull-proof connectors with tight-structure cable, where tight and loose are defined as whether movement is permitted between the outer jacket and the strength member.

Additionally, there are also some other considerations about fiber optic cable bend radius. This is a great concern for this delicate optical fiber since time-to-failure decreases precipitously with increasing bend stress. Much of the bend radius can be ameliorated with the addition of service loops, along with a scrupulous adherence to maintaining the fiber bend radius larger than one inch during installation in addition to final dressing and operation.

Fiber bending occurs in more than one way. Both installation and thermal cycling can result in internal stresses within the cable that create compression "ripplesâ€. In other words, multiple bends may occur within the body of the cable of extremely small radius, which greatly increases the possibility of cable failure.

When a fiber optic cable is seated against the face of a connector, the face of the cable core and cladding will be pushed into the body of the cable by a very small amount, on the order of millimeters, at both ends. Moreover, when a fiber cable is subjected to thermal cycling, swinging back and forth between the extremes of its operating temperatures, this can cause the cable jacket to shrink slightly. In both cases, the result is that the cable core and cladding become compressed within the jacket, and is not free to move in a manner that would relieve the stress. This increases light loss across the fiber and heightens the chance for what’s called a "blocked cable failure†(shown below).

These issues can be addressed via thermal preconditioning, the use of service loops, and limits placed on the restriction of fiber movement. Lastly, the use of an optical backscatter reflectometer can also return useful information about the internal structure of a fiber-optic cable, including very small compression-caused bends within the jacket.

Owing to its speed, weight-saving benefits, fiber optics has been considered as the basic clay of the telecommunications and commercial IT industries. As a professional fiber optic product manufacturer, Fiberstore supplies all kinds of fiber cables with different connectors, like LC fiber cable, MTP cable, SC fiber optic cable, etc.. You can visit Fiberstore for more information about fiber optic cables.

Posted by: fernxu123 at

02:25 AM

| No Comments

| Add Comment

Post contains 878 words, total size 8 kb.

August 04, 2016

When it comes to the topic of fiber optic cables, one word that comes into your mind at first thought usually is speed—the kind of blinding speed needed in high-performance computing for within-box processing as well as between-box communications. Except being somewhat expensive, fiber optic cables have been widely utilized for high-speed connections where their advantages, such as large capacity and long distance, outweigh the cost. Nowadays, the growing higher-speed connectivity requirements are pushing fiber optic technology into more use, typically in servers and long-haul connections. Fiber optics has been adopted as the basic clay of the telecommunications and commercial IT industries, not to mention thousands of miles of high-performance optical networks currently connecting corporations and research institutions around the world.

Just from theory, optical system is simple. There is a light source at one end and a detector at the other. The light goes through the cable and it is not affected by electromagnetic noise like a wired connection. While there is signal loss, it is significantly less than a wired connection, making fiber the preferred method for long distance connections. Laser diodes or LEDs are the usual light source. Lasers include fabry-perot (FP), distributed feedback (DFB), and vertical cavity surface-emitting lasers (VCSEL). Detectors include silicon photodiodes and germanium or InGaAs (indium gallium arsenide) photodetectors.

Fiber optic cable is terminated with the same or different connectors, available in single-mode and multi-mode types, like LC LC multimode patch cord (image below). Often, single-mode fiber (SMF) has a smaller diameter than multi-mode fiber (MMF), and is normally used with a laser source supporting higher bandwidths and longer distances.

In consumer applications, fiber optic cables are usually the case where the connection quality and longer distances offset the cost. The typical connections include high-speed serial interfaces such as USB, Thunderbolt, and PCI Express. Fiber connections are also available for display technologies like DisplayPort and HDMI. In addition, fiber has been used in digital audio applications. S/PDIF (Sony/Philips Digital Interface Format) jacks are common on audio boards and components, including amplifiers and HDTVs.

S/PDIF utilizes a passive fiber optic cable with the emitters and detectors embedded in the devices. Most other fiber-based systems employ an active cable with electronics at both ends.

In the past, fiber optic cables have been widely used in networking, especially in Ethernet. Other networking and storage technologies that support optical connectivity include FibreChannel and InfiniBand. Most of the network adapters and switches embed the transceivers in the hardware or provide a small form-factor pluggable (SFP) interface (image below). (Certainly, there are QSFP+ interfaces to handle 40 Gbit/s.). SFP modules include the optical transceivers and optical connections. Modules can support different passive cable connections including ST, FC, SC, and LC. This allows the cable lengths to be tailored to the installation.

Fiber optic cables use light to carry information. Light has a very high frequency that enables it to carry much more information at any given time. This makes fiber optic cables ideal for applications that use up a lot of bandwidth, like streaming music or video conferencing. Perhaps more importantly, fiber optic cables can carry data much farther than regular copper cables.

Besides, fiber optic cables are made of glass, which means they are not affected by electrical fields. These cables don't need to be grounded because they are not vulnerable to any type of electrical interference that can interrupt or interfere with signals. Fiber optic cables can even be used outdoors because they are immune to atmospheric conditions, including lightning. For those who may be a bit paranoid, another bonus advantage of fiber optic cables is that they can't be tampered with or tapped into as easily as copper wires.

Glass doesn't corrode, meaning that fiber optic cables can endure even the harshest conditions, like outdoors, under soil, or even near chemicals. There's virtually no chance of fire or shock in fiber optic cables because they don't use any electrical energy.

More and more requirements of high-speed connectivity are pushing fiber optic cables in both consumer and enterprise applications, as well as driving multiple fiber connections for building out the cloud to meet the demand for the Internet of Things (IoT). As a professional fiber patch cord manufacturer, Fiberstore provides various kinds of fiber optic cables for high-performance optical networks, LC fiber cable, SC fiber optic cable, ST ST fiber cable all included. You can visit Fiberstore for more detailed information about fiber optic cables.

Posted by: fernxu123 at

03:03 AM

| No Comments

| Add Comment

Post contains 765 words, total size 6 kb.

August 01, 2016

As fiber optic technology develops much maturer, and is widely deployed for private or public applications nowadays, the medium used for signal transmission, fiber optics, or more specifically, fiber optic cable, has become an essential part in fiber optic communications. And in home or business networks, fiber optic installations have seen obvious growth with days passing by. When they are chosen for networks, the installation isn’t a difficult task for installers, especially for those who have the training and qualifications required for the installation job. Generally speaking, in the whole cabling installation process, there are mainly three aspects that call for attention: general cabling guidelines, preparation phrase, and installation process. This text will detail these three aspects respectively.

Fiber optic cable is a cluster of glass fibers through which light pulses travel and transmit data at high speeds. Its ends are terminated with the same or different connectors, like LC-SC multimode fiber patch cord whose ends are capped with LC, and SC. Since fiber’s core is glass, the cable needs great attention. It’s ill-advised to crush, stress or overbend fiber optic cable. Every cable has values for minimum bend radius and maximum tensile loading, and it’s unwise to exceed these values. Besides, cables should never be allowed to hang freely for long distances or to press against edges in an installation.

In some cases, some applications may present conditions where the configuration of the equipment will damage the cable by overbending it if precautions are not taken. Conduit bends, pull boxes and joints must be checked to verify that the bend radius is not too small. Innerduct or flexible conduit can be used to ease or sweep the cable around tight corners. The inside radius of conduit bends for fiber optic cable should be at least 10 times the diameter of the cable.

Before installing cables whether for home networking or business, it’s necessary for users to have a written plan and a carefully drawn schematic. Documentation of the design helps users identify any potential problems before they begin their installation. In addition, a design or plan keeps users on track as they move through the strenuous process of installing the cables.

- Component Selection & Cost Estimation

Before installation, it’s imperative for users to estimate the cost of components included in the installation, like the fiber optics cables, the cable ties, the connectors, the closures, the wall jacks, the splices, and so on. For more complex projects, they may need to create a chart listing where each piece of cable or other equipment will be used. Completing a fiber optics installation can be costly, so users should look around for good quality paired with bargain prices.

After the necessary parts are assembled, users should check everything to ensure that there is no damage done to any of the components. The items should be stored in a secure, dry location until the work begins. Since fiber optic cables tend to set in the contour in which they are stored, the cables should be coiled in a figure eight orientation to keep them flexible.

For the entire network installation, it’s no doubt that installing the new cables is potentially the most difficult and complicated part. If the preparation and planning have been carefully executed, the installation may run more smoothly. But users still need a professional on hand to carry out the plan and to provide the necessary hands-on expertise.

- Spare Extra Cable Length

When users work on installation task, it’s a good idea to have plenty of extra cable on hand. Each length of cable should be a few inches longer than the space requires, allowing room for unforeseen obstacles. There should also be some slack so that the cable will not be overstretched.

- Test Components

As users assemble their network, they should test each section of it. This process brings to light any potential problems or incompatibilities before the entire network is in place. If a problem isn’t discovered until after it is assembled, users will have much more difficulty identifying the location of the malfunction. Each component throughout the network should also be tested for compliance to industry standards, and any cables that are being run through a firewall will need to be fire-stopped.

- Pull Cables

An underground channel for fiber optics should be about two inches in diameter. If there is a possibility that additional cables will be added in the future, the conduit should be larger, around four inches in diameter. If the fiber optics cables are being installed in a building, users should avoid bends and opt instead for straight runs through the space within a wall or ceiling.

Cable is typically run or pulled through the space using a rope or a heavy line as a guide. The longer the amount of cable being pulled, the thicker the guide rope should be. The person pulling on the far end should be able to instantly and clearly communicate with the person feeding the cable. It may be necessary to stop the pull to keep from snagging and ruining the cable or to navigate around an obstacle. Some experts suggest using walkie - talkies for communication during this part of the process. A special type of cable lubricant can be used to help the cable slide through the conduit or other space without snagging on objects or corners.

Cables should be labeled on each end. If there are multiple cables running through the same space, they should be secured together with cable ties to maximize space and to minimize tangling.

- Install Cable Protectors

Any cables running across a floor can be a hazard to those walking through the room. In an office or retail location, a loose cord can cause a customer or employee to fall, which may result in a lawsuit that costs the business a significant amount of money. To lessen the hazard factor, users should put cable protectors over any fiber optic cables that have to cross floor space.

Once all the cables are run through the appropriate spaces and all of the closures and wall jacks are in place, the computers and other devices can be hooked up and turned on. If users can access the Internet, they will know that everything has been correctly installed and that their service provider has switched the building to fiber optic service.

It’s easy to find many suppliers and sellers who deal with fiber optic installation components. However, it’s Fiberstore who offers really reasonable prices and fast delivery. Additionly, its products necessary for fiber optic network are all in large numbers of different kinds, such as fiber optic cables, connectors (SC, LC, ST, MTP), compatible fiber optic transceivers (Cisco Linksys MGBSX1, Intel E10GSFPLR, Juniper QFX-QSFP-40G-SR4), etc.. You can try it.

Posted by: fernxu123 at

09:34 AM

| No Comments

| Add Comment

Post contains 1140 words, total size 8 kb.

32 queries taking 0.1382 seconds, 80 records returned.

Powered by Minx 1.1.6c-pink.