August 01, 2016

As fiber optic technology develops much maturer, and is widely deployed for private or public applications nowadays, the medium used for signal transmission, fiber optics, or more specifically, fiber optic cable, has become an essential part in fiber optic communications. And in home or business networks, fiber optic installations have seen obvious growth with days passing by. When they are chosen for networks, the installation isn’t a difficult task for installers, especially for those who have the training and qualifications required for the installation job. Generally speaking, in the whole cabling installation process, there are mainly three aspects that call for attention: general cabling guidelines, preparation phrase, and installation process. This text will detail these three aspects respectively.

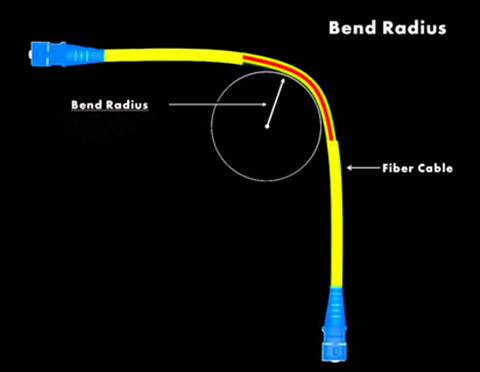

Fiber optic cable is a cluster of glass fibers through which light pulses travel and transmit data at high speeds. Its ends are terminated with the same or different connectors, like LC-SC multimode fiber patch cord whose ends are capped with LC, and SC. Since fiber’s core is glass, the cable needs great attention. It’s ill-advised to crush, stress or overbend fiber optic cable. Every cable has values for minimum bend radius and maximum tensile loading, and it’s unwise to exceed these values. Besides, cables should never be allowed to hang freely for long distances or to press against edges in an installation.

In some cases, some applications may present conditions where the configuration of the equipment will damage the cable by overbending it if precautions are not taken. Conduit bends, pull boxes and joints must be checked to verify that the bend radius is not too small. Innerduct or flexible conduit can be used to ease or sweep the cable around tight corners. The inside radius of conduit bends for fiber optic cable should be at least 10 times the diameter of the cable.

Before installing cables whether for home networking or business, it’s necessary for users to have a written plan and a carefully drawn schematic. Documentation of the design helps users identify any potential problems before they begin their installation. In addition, a design or plan keeps users on track as they move through the strenuous process of installing the cables.

- Component Selection & Cost Estimation

Before installation, it’s imperative for users to estimate the cost of components included in the installation, like the fiber optics cables, the cable ties, the connectors, the closures, the wall jacks, the splices, and so on. For more complex projects, they may need to create a chart listing where each piece of cable or other equipment will be used. Completing a fiber optics installation can be costly, so users should look around for good quality paired with bargain prices.

After the necessary parts are assembled, users should check everything to ensure that there is no damage done to any of the components. The items should be stored in a secure, dry location until the work begins. Since fiber optic cables tend to set in the contour in which they are stored, the cables should be coiled in a figure eight orientation to keep them flexible.

For the entire network installation, it’s no doubt that installing the new cables is potentially the most difficult and complicated part. If the preparation and planning have been carefully executed, the installation may run more smoothly. But users still need a professional on hand to carry out the plan and to provide the necessary hands-on expertise.

- Spare Extra Cable Length

When users work on installation task, it’s a good idea to have plenty of extra cable on hand. Each length of cable should be a few inches longer than the space requires, allowing room for unforeseen obstacles. There should also be some slack so that the cable will not be overstretched.

- Test Components

As users assemble their network, they should test each section of it. This process brings to light any potential problems or incompatibilities before the entire network is in place. If a problem isn’t discovered until after it is assembled, users will have much more difficulty identifying the location of the malfunction. Each component throughout the network should also be tested for compliance to industry standards, and any cables that are being run through a firewall will need to be fire-stopped.

- Pull Cables

An underground channel for fiber optics should be about two inches in diameter. If there is a possibility that additional cables will be added in the future, the conduit should be larger, around four inches in diameter. If the fiber optics cables are being installed in a building, users should avoid bends and opt instead for straight runs through the space within a wall or ceiling.

Cable is typically run or pulled through the space using a rope or a heavy line as a guide. The longer the amount of cable being pulled, the thicker the guide rope should be. The person pulling on the far end should be able to instantly and clearly communicate with the person feeding the cable. It may be necessary to stop the pull to keep from snagging and ruining the cable or to navigate around an obstacle. Some experts suggest using walkie - talkies for communication during this part of the process. A special type of cable lubricant can be used to help the cable slide through the conduit or other space without snagging on objects or corners.

Cables should be labeled on each end. If there are multiple cables running through the same space, they should be secured together with cable ties to maximize space and to minimize tangling.

- Install Cable Protectors

Any cables running across a floor can be a hazard to those walking through the room. In an office or retail location, a loose cord can cause a customer or employee to fall, which may result in a lawsuit that costs the business a significant amount of money. To lessen the hazard factor, users should put cable protectors over any fiber optic cables that have to cross floor space.

Once all the cables are run through the appropriate spaces and all of the closures and wall jacks are in place, the computers and other devices can be hooked up and turned on. If users can access the Internet, they will know that everything has been correctly installed and that their service provider has switched the building to fiber optic service.

It’s easy to find many suppliers and sellers who deal with fiber optic installation components. However, it’s Fiberstore who offers really reasonable prices and fast delivery. Additionly, its products necessary for fiber optic network are all in large numbers of different kinds, such as fiber optic cables, connectors (SC, LC, ST, MTP), compatible fiber optic transceivers (Cisco Linksys MGBSX1, Intel E10GSFPLR, Juniper QFX-QSFP-40G-SR4), etc.. You can try it.

Posted by: fernxu123 at

09:34 AM

| No Comments

| Add Comment

Post contains 1140 words, total size 8 kb.

35 queries taking 0.0806 seconds, 80 records returned.

Powered by Minx 1.1.6c-pink.